It's been a while since I've posted. I've journeyed to places where the internet does not exist and have returned with a lot of bricks and mortar for quite an epic project I've got in mind, so that's taken a lot of time, but fear not! I've been working on several things in the meantime - one of which is learning about surface mount soldering.

Ah yes, BGA! A real problem child for hobby electronics. Ball Grid Array components consist of a small plastic electronics package with no legs. Instead, all the connections are made by small balls of solder that live underneath the package. It's impossible to solder with an iron and typically requires a reflow oven or similar tool.

A project I'm working on requires a BGA component so I thought I'd find a smaller project first to test on. I settled on the TinyFPGA which seems to be quite a popular project. The parts are cheap enough. I live in the USA at the moment so using Digikey and OshPark aren't bad options.

I've not got a soldering oven so I bought a hotplate. I've a few uses for it and I thought I could use it to solder this thing up. Firstly, you'll need some solder paste. This consists of a syringe filled with a grey goop. Inside this goop are a load of tiny solder balls. It can be applied with the syringe though a lot of people use a solder stencil. I've found I didn't need one for this small a board but I guess for a larger project, it makes it a little easier.

At first I tried to use a frying pan on top of my hotplate in order to spread the heat a little more evenly. It seemed to work-ish, but it took quite a while. At first the paste goes even greyer (if thats possible) and seems to spread everywhere but eventually, it goes shiny and pulls everything into place.

I used a small amount of flux compound underneath the BGA component. It's a brown waxy paste that comes in a jar - Flux 135 apparently.

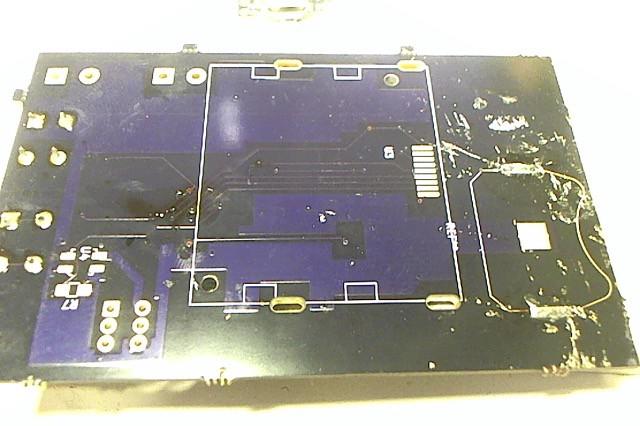

I suspect some of the PCB layers may have burned a little as parts of the board might have gotten too hot. There are some marks on it sadly. I tried to program it with the Arduino method described by the creator of the FPGA but I found it didn't work. Damn shame! I suspect something has gone wrong with my soldering, which is a bit of a waste.

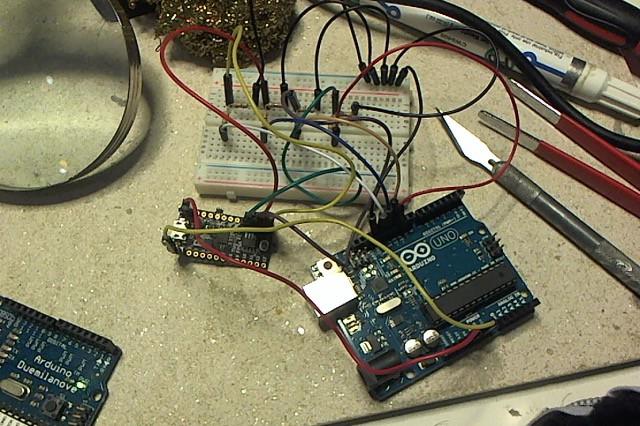

I recently finished my hydroponic controller design - well the first version anyway. Most of the components I soldered on by hand but I made a mistake and the ATMEL chip in the middle had slipped. I thought that I could never fix it but I got chatting with a few knowledgeable folks and it turns out, I can use my hotplate to reflow a component that has gotten stuck.

I was told I needed to check a few things. Firstly, different solder melts at different temperatures. In addition hotplates tend to vary a bit so it's useful to turn them up, then turn them back a bit until they settle at a reasonably high temperature. In order to know the temperature, a laser thermometer was suggested, so back off to eBay I went.

The foil I found hard to use. It doesn't actually increase in temperature very much. This is all due to the specific heat capacity of the foil. Not a lot of mass there. The idea being this disperses the heat more evenly. Despite what I tried though, I couldn't get the solder to melt.

I made the mistake of placing the board directly onto the plate. I did work, in that I could move the chip back into the right place, but some of the board did start to burn a bit as you can see in the image below. I suspect some of the solder mask has burned away.

Well, the power section on my board works, so that's something. Using the correct solder, enough flux and getting the temperature properly settled is definitely the way to go. I'm told that serious folks have managed to solder much more complicated boards on their kitchen hobs, so I'm sure this can be done right. Practice makes perfect though.

One suggestion has been to pickup a toaster oven which are popular over here in the USA, so that might be something I investigate in the future.